- 503Pharma

- Posts

- 503Pharma Compliance Intelligence

503Pharma Compliance Intelligence

Five Potency Failures. HVAC Down for 3 Months. Products Dispensed Anyway.

Welcome back to 503Pharma Compliance Intelligence.

We've covered interstate shipping, environmental monitoring, and PIC supervision. This week: an FDA inspection from October 2024 that shows what happens when quality systems exist on paper but not in practice.

The violations? Out-of-spec thyroid compounds dispensed to patients. A broken HVAC system ignored for months. Contamination visible on every surface.

Let's get into it.

📋 THIS WEEK'S CASE

503A Non-Sterile Compounding Pharmacy | Florida

FDA 483 Issue Date: October 4, 2024

Inspection Period: October 1–4, 2024

Key Products: Thyroid compounds (T3/T4), Testosterone cream, Progesterone capsules

Observations:

2 major observations on FDA Form 483

5 potency failures identified

Multiple lots dispensed to patients before failures addressed

WHAT HAPPENED

FDA investigators arrived at this Florida pharmacy in early October 2024. Over three days, they documented a pattern of quality system failures that had been compounding—literally—for months.

Five products failed potency testing. All were dispensed to patients.

The pharmacy's contract lab identified these failures:

Testosterone 2mg/mL cream: 85.5% of label claim

Liothyronine (T3) bulk: 77.3% of label claim

Levothyroxine (T4) bulk: 121.8% of label claim

Levothyroxine (T4) bulk: 148.3% of label claim

Liothyronine (T3) bulk: 84.4% of label claim

The T3 and T4 bulk lots were used to produce multiple finished product batches—all dispensed to patients.

The HVAC had been down since June.

The hazardous room's HVAC unit stopped working on June 24, 2024. When investigators checked on October 2nd—more than three months later—the room temperature was 26.3°C.

The pharmacy was still compounding. Still storing hazardous bulk drug substances. Still filling progesterone capsule prescriptions that required controlled environmental conditions.

WHAT'S AT STAKE

This wasn't a sterile compounding facility. No ISO classifications. No media fills. Just a traditional 503A pharmacy making creams, capsules, and topical preparations.

And that's the point.

The FDA's Insanitary Conditions guidance applies to non-sterile compounding too. Environmental controls matter for potency. Temperature excursions affect stability. Contamination risks exist even without sterility requirements.

The observations went beyond the HVAC:

White powder residue on ALL surfaces—refrigerator, countertops, bulk containers, AC units

A technician placed her soiled gloved finger directly into a finished testosterone cream to remove residual product

A dirty, ripped towel used to wipe gloved hands and clean powder from the hood

Both non-hazardous hoods had chipped, discolored grates—still in use, no corrective action

WHY THIS MATTERS FOR ALL OF US

This pharmacy had lab testing. But testing without action is just documentation of failure.

Here's what we can learn:

1. OOS results require immediate action.

Five potency failures. Products still dispensed. The testing caught the problem—the quality system didn't respond. An OOS result should trigger quarantine, investigation, and a decision. Not continued dispensing.

2. Environmental controls aren't optional for non-sterile.

Three months with no HVAC in a hazardous compounding room. No documented corrective action. No alternative controls. The fact that it's "just" non-sterile compounding doesn't exempt you from maintaining appropriate conditions.

3. Contamination is visible if you look.

Powder on every surface. A dirty towel used for cleaning. These aren't hidden problems—they're obvious to anyone paying attention. If an FDA investigator can see it, so can you.

4. Equipment issues need documentation and action.

Chipped paint on hood grates. Damaged equipment continued in service. No maintenance records. No corrective action plans. When something breaks or degrades, document it and fix it—or stop using it.

🛡️ BUILDING SYSTEMS THAT CATCH THIS

Testing is only valuable if you act on the results. Environmental monitoring only works if you maintain the environment.

Here's how CompoundLearn helps you stay ahead:

Training Modules

Build competency in quality oversight with DP-1: Quality Oversight & Deviation Management and DP-3: Environmental Controls & Monitoring—so your team understands when and how to respond to OOS results and environmental excursions.

SOP Library

Access ready-to-use procedures for OOS investigations, environmental monitoring, and equipment maintenance. Don't reinvent the wheel—customize proven templates.

Competencies

Assign and track role-specific qualifications. Ensure the person reviewing lab results knows what an OOS finding requires. Document who's trained on what.

Templates

Generate environmental monitoring logs, equipment maintenance records, and deviation reports. Audit-ready documentation that takes seconds to create.

Assessments

Verify that your team can identify contamination risks and respond appropriately. Document the results automatically.

One unified system for training, documentation, and compliance.

A 483 for failures you already knew about. Or a system that ensures you act on what you find.

✅ THIS WEEK'S ACTION ITEM

Review your last 90 days of lab results.

Pull every COA from your testing lab. Flag any results outside specification. For each one, document: (1) Was the product quarantined? (2) Was an investigation completed? (3) What was the disposition decision?

If you can't answer those questions for every OOS result, you have a gap.

Takes 30 minutes. Prevents a 483.

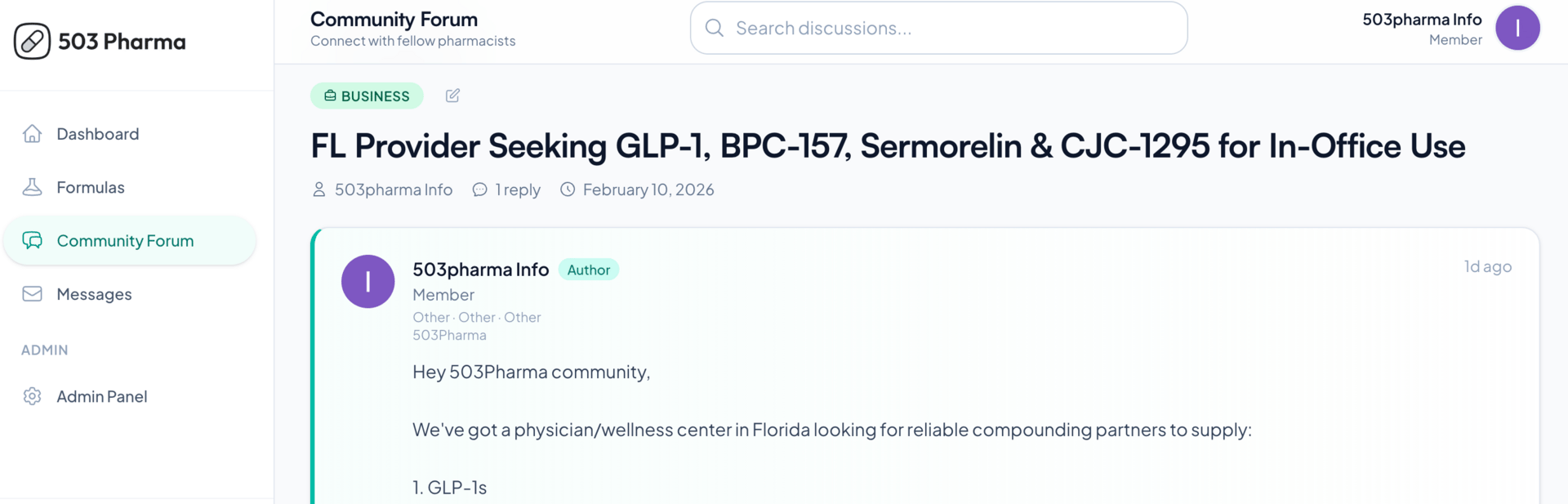

You’re Invited: Free, Invite-Only Community for Compounding Pharmacies Now Live!

Sign up at: app.503pharma.com !

Community Discussion Forum — Connect with peers, ask questions, and share insights on compounding, compliance, business operations, and industry news

Professional Profiles — Build your profile with your credentials, specialty areas, and organization to connect with the right people

Direct Messaging — Have private conversations with other members in the community

Formula Request Network — Submit and discover compounding formula requests from pharmacies across the network

Reply and tell us: Was this useful? What would make it better?

✉️ That’s your 503Pharma Intel Brief. Our mission is to keep compounding professionals informed, prepared, and ahead of the curve.